Understanding Electromagnetic Shielding Materials

What Are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances that are used to protect sensitive electronic devices from electromagnetic interference (EMI). They work by reflecting, absorbing, or rerouting electromagnetic waves, thereby preventing disturbances that can adversely affect the performance of electronic circuits and devices. The importance of these materials has surged as the reliance on electronic devices grows, especially in applications ranging from mobile phones to sophisticated medical equipment. Electromagnetic shielding materials come in various forms, each adapted for specific applications and performance criteria.

Importance of EMI Shielding in Modern Technology

As technology advances, the density of electronic components in devices increases, leading to an amplification of potential electromagnetic interference. EMI can arise from both internal components (like processors) and external sources (such as power lines and radios). Effective shielding is vital in ensuring the reliability of modern technology, which is often compact and complex. The ability to maintain signal integrity without degradation due to interference is essential for ensuring the optimal functioning of both consumer electronics and critical infrastructure systems.

Types and Variations of Electromagnetic Shielding Materials

Electromagnetic shielding materials can be classified into several categories based on their composition and application methods. Some common types include metallic shields, conductive coatings, and composite materials. Each type has unique properties that dictate its effectiveness in different environments. For instance, while metals are generally effective for a wide range of frequencies, composite materials may offer enhanced flexibility and durability for specific applications.

Common Materials Used in Electromagnetic Shielding

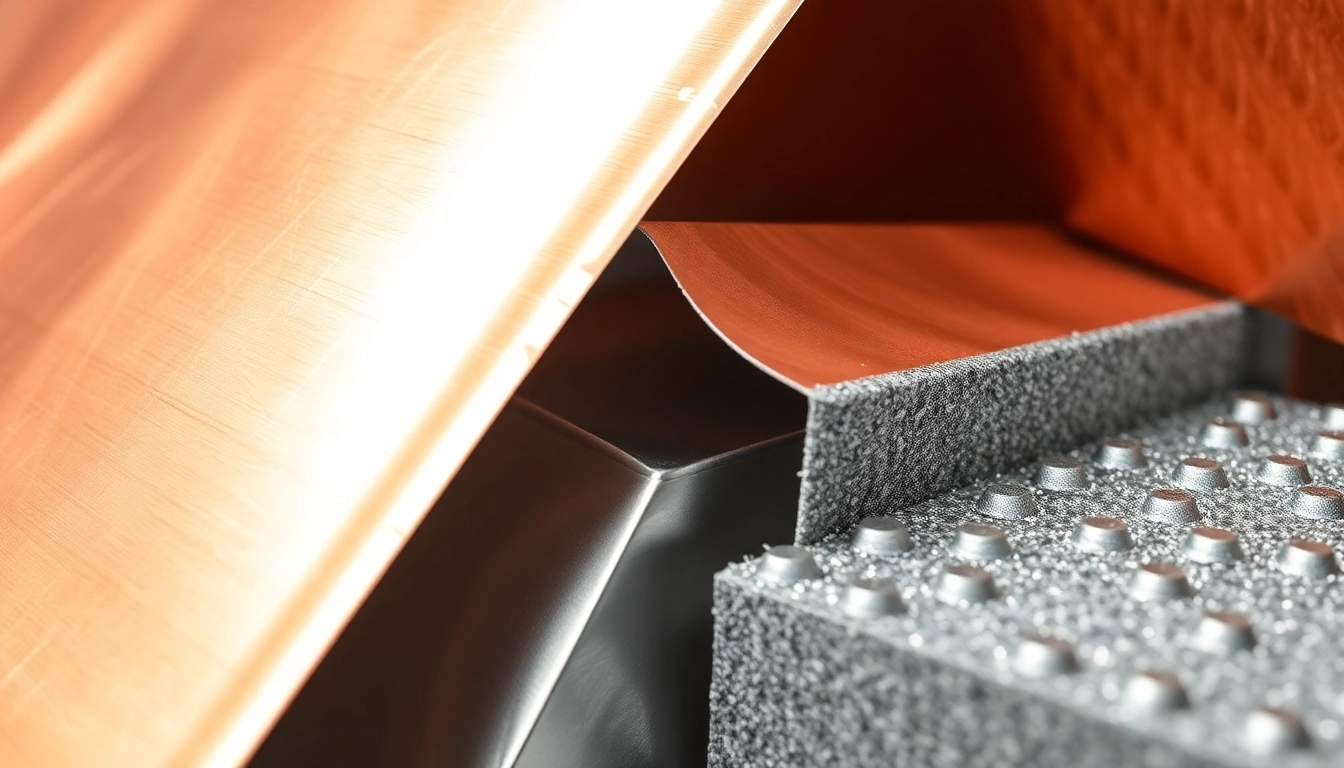

Metals: Copper, Aluminum, and Steel

Metals serve as the backbone of effective electromagnetic shielding due to their high electrical conductivity and potent reflective properties. Copper is often regarded as the gold standard in EMI shielding because of its excellent attenuation characteristics across a broad frequency spectrum. Aluminum is another practical choice, particularly for lightweight applications, while steel provides added strength and rigidity, making it suitable for heavy-duty shielding requirements. The choice of metal influences the effectiveness, cost, and application method used for EMI shielding.

Advanced Composites for Enhanced Shielding

Alongside traditional metals, advanced composites have emerged as a viable alternative for electromagnetic shielding. These materials are often engineered by combining conductive and non-conductive materials, creating a lightweight yet effective barrier against EMI. Carbon-based composites have gained attention for their balance of performance and weight, along with environmental resilience. Innovations in nanotechnology have also led to the development of nanocomposites, which exhibit unprecedented shielding effectiveness thanks to their unique structures.

Conductive Polymers and Their Applications

Conductive polymers have become increasingly popular in the field of EMI shielding due to their flexibility and ease of processing. These materials combine the lightweight properties of plastics with the electrical conductivity necessary for effective shielding. Applications for conductive polymers range from flexible electronic circuits to lightweight coverings in aerospace and automotive industries. Their compatibility with various substrates enhances their usability in a diverse range of designs and manufacturing processes.

How to Select the Right Electromagnetic Shielding Material

Factors to Consider in Material Selection

When choosing the right electromagnetic shielding material, several factors must be considered, including:

- Frequency Range: Different materials are effective over different frequency ranges, so it is crucial to understand the spectrum of the electromagnetic interference expected.

- Mechanical Properties: The material’s strength, flexibility, and durability must align with the application requirements to ensure it can withstand environmental stress.

- Cost: Budget constraints often play a significant role in material selection; understanding the cost versus performance balance is essential.

- Environmental Considerations: Some applications may require materials to withstand extreme temperatures, humidity, or exposure to chemicals.

Applications for Various Shielding Materials

The choice of shielding material heavily depends on the application. For consumer electronics, lightweight and cost-effective materials like aluminum are often favored. In contrast, critical infrastructure applications, such as those found in medical devices or aerospace, prioritize high-performance materials like copper or sophisticated composites for their reliability and effectiveness. Understanding specific application needs helps narrow down the appropriate materials for successful implementation.

Case Studies: Successful Implementations

Numerous case studies illustrate the successful use of electromagnetic shielding materials in various industries:

- Medical Devices: In MRI machines, where electromagnetic fields are prevalent, copper shielding ensures clear imaging results by minimizing interference.

- Aerospace: Utilizing advanced composites allows for structural integrity while significantly reducing weight, essential in aircraft design.

- Consumer Electronics: Smartphones often incorporate conductive plastics which allow for the shielding of sensitive components without adding bulk.

Performance Metrics for Electromagnetic Shielding

Evaluating Shielding Effectiveness

The effectiveness of electromagnetic shielding is typically evaluated using metrics such as the Shielding Effectiveness (SE), measured in decibels (dB). SE indicates how much electromagnetic energy is attenuated by the shielding material. A higher dB value signifies a more effective shield. Understanding this metric is vital for designers aiming to ensure that their chosen materials meet the required standards for specific applications.

Testing Standards: What You Need to Know

Various testing standards exist to assess the effectiveness of electromagnetic shielding materials. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provide guidelines for testing methods and establishing compliance benchmarks. Often, tests will cover different environmental conditions and signal frequencies to ensure comprehensive evaluation.

Real-World Examples of Shielding Success

Real-world applications demonstrate the practical effectiveness of various shielding materials. For example, in automotive environments, conductive coatings applied to the interiors of vehicles ensure that sensitive electronic systems operate without interference from external electromagnetic sources. Particularly in electric vehicles, where strong magnetic fields may occur, advanced shielding techniques are crucial for safety and performance.

Future Trends in Electromagnetic Shielding Materials

Innovations in Conductive Materials

The future of electromagnetic shielding is promising, with ongoing research into innovative conductive materials. Graphene-based materials are being explored for their superior conductive properties and mechanical strength. Furthermore, the integration of smart materials that can adapt to varying electromagnetic environments may revolutionize shielding technologies. These innovations could lead to thinner, lighter, and more versatile shielding solutions suitable for a broader range of applications.

Eco-Friendly Shielding Options

With growing awareness of environmental sustainability, there is an increasing demand for eco-friendly electromagnetic shielding solutions. Researchers are working to develop biodegradable or recyclable shielding materials that maintain performance without compromising environmental integrity. Plant-based composites and other sustainable materials are entering the market as viable alternatives to traditional options.

Predictions for Industry Developments

As the market for electronic devices expands globally, the demand for efficient electromagnetic shielding materials will continue to grow. Industry experts predict that advancements in nanotechnology and sustainable materials will shape the future of EMI solutions. Companies will increasingly seek materials that not only mitigate interference but also contribute to energy efficiency and environmental consciousness, aligning with broader global sustainability goals.