Understanding Pipe Stands

What Are Pipe Stands?

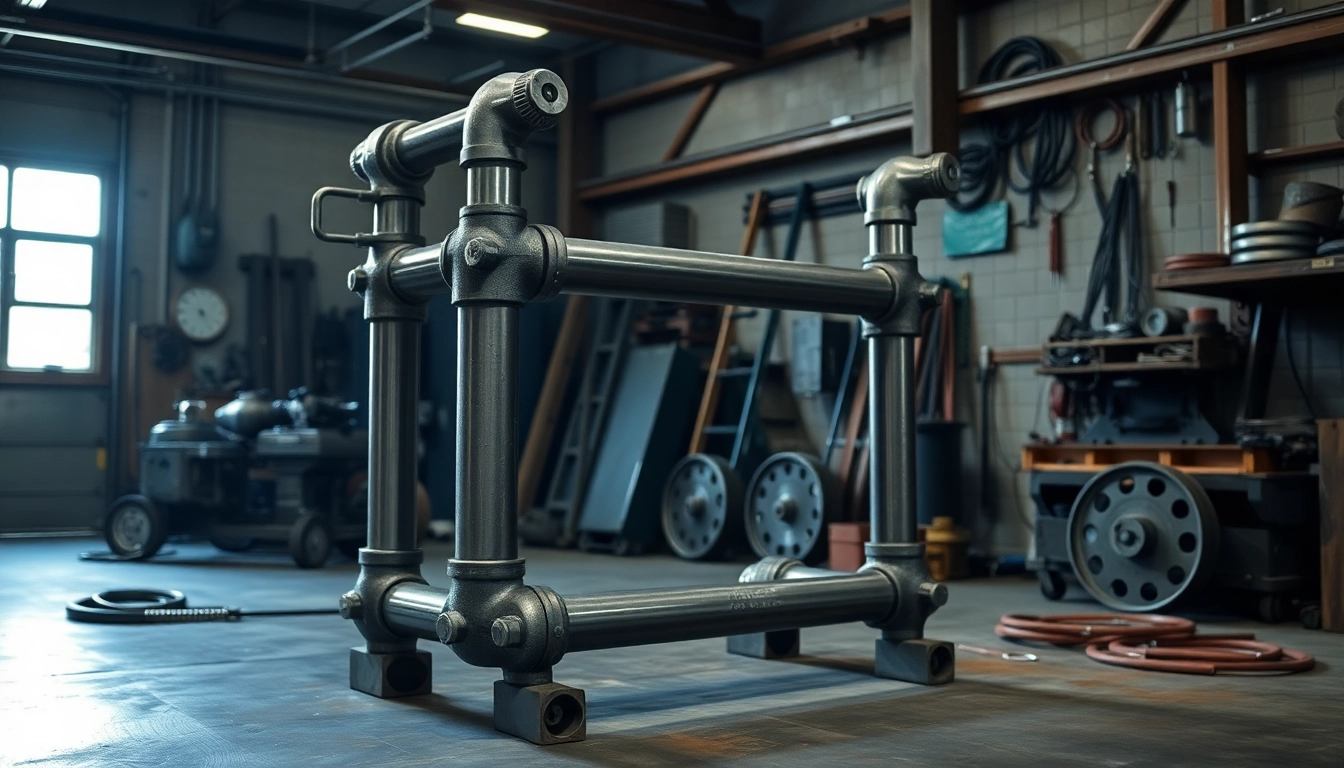

Pipe stands are essential tools used predominantly in welding, construction, and plumbing industries to support and stabilize pipes during various operations, including cutting, welding, and assembling. These stands provide reliable support, ensuring that pipes and materials remain in a fixed position, which is crucial for achieving high-quality workmanship. The design of pipe stands allows them to handle substantial loads while maintaining ease of use.

Commonly made from robust materials like steel, these stands are engineered to withstand the weight of heavy pipes, enhancing safety and productivity on the job site. Many professionals and DIY enthusiasts utilize pipe stands in various applications, taking advantage of their durability and adjustable features.

Key Features of Quality Pipe Stands

When selecting pipe stands, several key features should be considered to ensure that they meet specific requirements:

- Weight Capacity: Quality pipe stands should cater to various weight capacities to support different pipe sizes and applications. Some stands can support loads up to 2,500 lbs, making them suitable for heavy industrial use.

- Adjustable Heights: Many pipe stands offer adjustable height settings, allowing for versatility in positioning and the ability to accommodate different pipe diameters and project requirements.

- Stability: A solid base and wide stance contribute to overall stability, preventing tipping and ensuring safety even when operating in challenging conditions.

- Material Quality: The durability of the materials used in the construction of pipe stands is vital. Steel is commonly preferred due to its strength and resistance to bending or breaking under pressure.

- Portability: Lightweight and collapsible designs enhance portability, allowing for easy transport between job sites without sacrificing strength.

Types of Pipe Stands for Different Applications

Various types of pipe stands cater to specific needs, and understanding the differences can be beneficial in selecting the right equipment:

- V-Head Pipe Stands: These stands feature a V-shaped head that cradles pipes securely, perfect for welding and cutting tasks. They are also great for larger diameter pipes.

- Roller Head Stands: Equipped with rollers, these stands allow for easy movement of pipes along the stand, which can be critical in assembly or installation jobs.

- Heavy-Duty Pipe Stands: Designed for maximum capacity and stability, heavy-duty stands are suited for the most demanding industrial applications.

- Folding Pipe Stands: These provide the best of both worlds: sturdy support when in use and compact storage after jobs are complete. Ideal for professionals who need to travel to multiple worksites.

Benefits of Using Pipe Stands

Improving Safety in the Workplace

Safety is paramount in any work environment, particularly in construction and welding, where heavy materials and equipment pose inherent risks. Pipe stands significantly enhance workplace safety by providing stable support for pipes. Properly supported pipes decrease the likelihood of accidents caused by shifting or falling materials.

Moreover, using pipe stands reduces physical strain on workers, as they can position materials at a comfortable height for operation. This ergonomic advantage can lead to fewer injuries related to bending and lifting, promoting a healthier workplace.

Enhancing Project Efficiency

Efficiency is key in any project, and the use of pipe stands contributes to this by enabling quicker setup and execution of tasks. With pipes securely held in place, workers can operate faster and with greater precision, minimizing delays caused by readjustments or alignment issues. This boost in productivity can have a ripple effect, leading to timely project completions and increased overall profitability.

Furthermore, the adjustable features of many pipe stands allow them to accommodate various tasks, making them versatile tools that reduce the need for multiple pieces of equipment. Thus, a single set of pipe stands can serve multiple purposes, adding to their value in the workplace.

Durability and Material Considerations

Durability in pipe stands is essential as these tools are often exposed to harsh environments, including extreme weather conditions and rigorous handling. High-quality materials, such as heavy-duty steel, enhance the lifespan of pipe stands and ensure they can withstand substantial weight without failure.

Investing in durable pipe stands translates to long-term savings, as they require fewer replacements and repairs over time. This consideration is particularly important for businesses looking to optimize their operational budgets without sacrificing safety or performance.

How to Choose the Right Pipe Stand

Weight Capacity and Stability

When choosing a pipe stand, it is critical to assess the weight capacity based on the types of pipes that will be supported. Underestimating load requirements can lead to equipment failure, posing safety risks and potential project delays. Before making a purchase, ensure the stand can handle the maximum expected weight.

Additionally, the stability of the pipe stand is crucial. Evaluate the design of the base and the material construction to ensure that it can remain stable under load without tipping or shaking. A stand that wobbles or shifts can be extremely dangerous when working with heavy materials.

Adjustable Heights and Versatility

Consideration of adjustable heights is essential for those who work with various pipe sizes or engage in different types of projects. Adjustable stands can be modified to fit higher or lower requirements, promoting versatility and efficiency in usage. Ensure that the range of height adjustments meets your specific project needs.

Furthermore, evaluate how versatile the stand is. Can it be used for multiple applications, including welding, plumbing, and installation tasks? A versatile pipe stand can save money and storage space by replacing multiple single-use tools.

Brand Comparisons and Recommendations

With numerous brands producing pipe stands, thorough research is paramount. Compare leading manufacturers based on factors such as material quality, user reviews, warranty provisions, and customer service support. Established brands may offer more trustworthy products, as they generally have rigorous quality control processes and responsive customer service.

Recommendations from industry professionals can also provide valuable insights. Engaging with online forums and specialist communities can yield first-hand experience regarding brand performance, ultimately guiding you towards the best choice for your needs.

Maintenance Tips for Longevity

Regular Inspection Guidelines

Regular inspection is crucial to ensuring the safety and functionality of pipe stands. Create a maintenance schedule that includes inspections before and after each project. During these inspections, look for signs of wear, damage, or corrosion. Ensuring that all components, such as locking mechanisms and adjustable heights, function properly is vital for maintaining safety standards.

Pay particular attention to any loose bolts or screws, which can compromise stability. Tightening hardware and replacing worn-out components promptly will enhance the lifespan of your pipe stands.

Cleaning and Rust Prevention

Maintaining cleanliness is essential for longevity. After each use, clean the pipe stands with mild soap and water to remove dust, debris, and any contaminants that may have accumulated. Ensure that they dry completely to prevent moisture-related issues.

Applying a protective coating or rust-inhibiting spray can also help prevent corrosion, especially in humid environments. Regular cleaning and protection will significantly extend the life of your stands, ensuring they remain reliable for years.

When to Replace Your Pipe Stands

Understanding when to replace your pipe stands is critical to maintaining safety on the job. Signs that replacement is necessary include visible damage, chronic instability, significant wear, or inability to hold the required weight securely. If a stand has sustained structural damage from heavy loads, it should be replaced to avoid potential hazards.

Additionally, if you find that your projects often require adjustments that are beyond the capabilities of your existing pipe stands, consider upgrading to a more versatile model that meets modern demands.

FAQs About Pipe Stands

Common Misconceptions

Some common misconceptions about pipe stands include the belief that all stands are created equal. In reality, the quality, design, and materials can vary immensely. Selecting the right pipe stand for your specific needs is crucial. Understanding the types and brands available can help ensure you’re making a wise investment.

Proper Usage Instructions

To ensure the safe use of pipe stands, always follow the guidelines provided by the manufacturer. Never exceed the weight capacity, and ensure the stands are on stable surfaces to prevent tipping. Regularly inspect stands for functionality before use, and train all workers on safety measures related to both the setup and operation of pipe stands.

Warranty and Customer Support Insights

Before purchasing, it’s vital to review the warranty that each brand offers. A solid warranty can provide peace of mind regarding the quality of the product and can protect you against defects. Exceptional customer support can enhance your overall experience, especially if you require assistance with issues or product inquiries. Brands recognized for superior customer service often stand out for their commitment to user satisfaction.